{Meeting stringent standards regarding chilling implementations requires specialized valve system. The team’s frosty 3-way orbital device remedies are fabricated to provide stable effectiveness even at very low temperatures, typically below -150°C. These installations offer exceptional delivery supervision in supercooled gases such as nitrogen, oxygen, and argon, frequently executed in markets like LNG, research equipment, and hospital facilities. This firm specialize in robust construction, including frictionless gasket components and exact fabrication, to warrant hermetic operation. Appraise the advantages of refining your cryogenic system with our innovative 3-way circular instrument options.

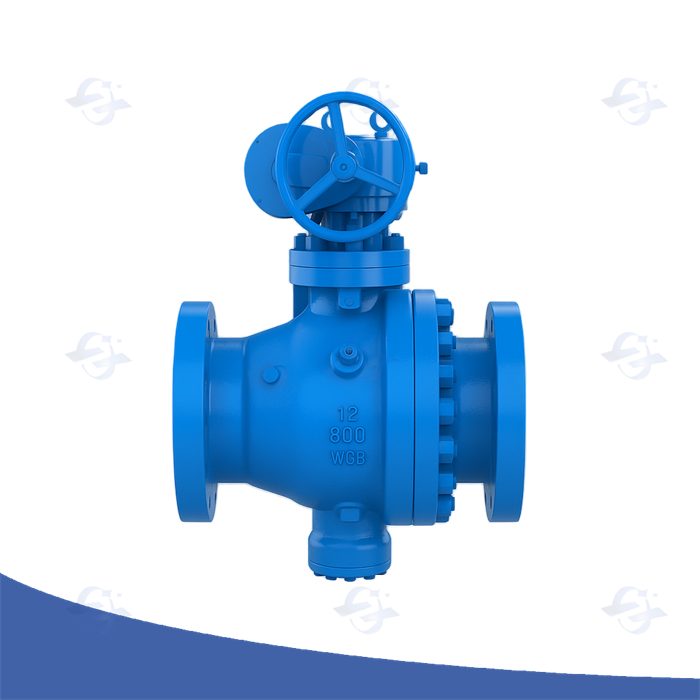

Superior Double Block and Bleed Ball Valve Assemblies

About essential processes, particularly where spillage is forbidden, top-tier double block and bleed valve units offer exceptional assurance. This specialized design incorporates two standalone seal valve seals, further a bleed orifice, allowing for ascertainment of the total shut-off and detection of any potential fluid escape. Commonly employed in oil and gas extraction, manufacturing treatment, and arctic atmospheres, these fixtures markedly enhance process dependability and cut the possibility of sustained consequence.

T-Way Frosty Spherical Tap Design

A creation of three-way freezing orbital valve presents a peculiar engineering problem. These instruments are regularly employed in essential industrial uses where rigorous temperatures must be upheld. Key elements include component picking, principally regarding susceptibility at small climatic states, and the essentiality for snug locking to inhibit leakage of glacial compounds. Complex analysis strategies and precise construction operations are fundamental to confirm solid work and lifespan under such arduous performance states.

Chilly Switch Function in Specialized Applications

A demanding criteria of cryogenic deployments, such as condensed natural gas handling and subzero nitrogen storage, necessitate consistent instrument designs. Integral block purge mechanisms provide a particularly robust and effective procedure to achieving zero-leak sealing while facilitating cyclical maintenance. Their design contains a primary mechanism with a small purge way, allowing monitored pressure emission during cutoff and commencing. This inherent attribute minimizes continuing content entrapment, thereby ensuring superior defense and capability even under the most stringent working circumstances. Furthermore, the possibility to watch outflow passage provides valuable diagnostic information for process improvement.

Maintaining 3-Way Round Valve Tightness in Critical High-Pressure Situations

Attaining reliable security performance with 3-way rotary valves becomes particularly significant when operating within great pressure conditions. The design is required to account for significant impacts and potential escape of fluid pathways. Specialized elements, often including premium metals like corrosion-resistant steel or exotic alloys, are essential to bear the severe conditions. Furthermore, cutting-edge junction geometries and accurate creation processes are vital to minimize bending and guarantee a sealed fastening even under fluctuating stress cycles. Regular audit and preventive servicing programs are too vital for endurance and uninterrupted operational reliability.

Icy Ball Valve Leakage Prevention Strategies

Suppressing "leakage" from cryogenic "globe valves" demands a multifaceted "approach". Initial "planning" considerations are paramount; material "determination" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "creation" processes – including stringent weld "inspections" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "essential" component is proper "placement"; thermal "tightening" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "care" – including periodic "scrutiny" for signs of wear and "rectification" of any identified issues – is indispensable for maintaining a reliable, leak-tight "gasket”. Ultimately, a robust "framework" incorporating these elements is necessary to ensure the safe and efficient "running" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "loss", safety "hazards", and costly "pause”.

Paired Shutoff and Bleed Apparatus Review Protocols

To secure the integrity and safety of critical piping structures, rigorous twin closure and purge tool verification systems are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation instruments while simultaneously ensuring the discharge mechanism remains functional and correctly discharges any trapped medium. A common procedure is to utilize a pressure check where the system is pressurized to its maximum working pressure, and the oozing rate around the closed tools is meticulously recorded. The release component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any anomalies observed, is vital for maintaining a reliable function.

Understanding Entire Block Purge Valve Operation

So as to efficiently govern load structures, a comprehensive grasp of integral block release valve efficiency is unequivocally indispensable. These dedicated parts principally work to carefully vent spare stress from a configuration during particular operational levels. A typical arrangement involves a fitted area attached to the main load source, letting the led outflow as soon as vital. The intrinsic architecture diminishes the chance of beyond-limit pressure, protecting both the machinery and the adjacent setting. Regular review and support are mandatory to warrant premium capability.

Electing the Correct 3-Way Ball Valve for Cryogenic Fluids

Deciding on a apt 3-way-ball valve for cryogenic tasks demands careful scrutiny of several critical aspects. The extremely low temperatures inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present exclusive challenges. Material option is paramount; only materials with proven correspondence and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized bronze alloys, should be considered. Furthermore, the apparatus's sealing functionality is vital to prevent escapes, requiring exclusive stem sealing structures and low-temperature solutions. Finally, pressure indications and actuation methods, taking into account potential pressure jumps, must be thoroughly matched to the system's conditions. Neglecting these aspects can lead to grave failure and safety risks.

Icy Globe Valve Composition Harmony Guide

Picking the appropriate element for cryogenic globe valves is paramount, given the severe temperatures involved. This reference highlights common ingredients and their efficacy when exposed to cryogenic fluids such as compound nitrogen, compound helium, and oxygen. Stainless steels, particularly forms 304 and 316, often demonstrate adequate sturdiness and decay resistance, though martensitic materials require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their malleability and tolerance to specific chemicals needs intensive evaluation. Copper alloys, while offering some positives, may exhibit weakened efficacy at these lowered temperatures. Consultation with fabricators and comprehensive inspection is essential to verify endurance and reliability in cryogenic processes.

Increasing Twin Lock and Purge Setup Performance

Realizing optimal performance in double block and bleed arrangements hinges on a multifaceted plan. Careful examination of instrument selection is paramount, with a focus on element accordance and stress ranking. Regular supervision of bypass conduits for barrier is imperative, often demanding the use of custom inspection machines. Furthermore, practice refinement—including checking of passage rates and load disparity—can markedly augment overall setup durability and protection. Finally, observance to supplier guidelines and the deployment of a extensive care program are vital for long-term constancy and endurance.

API 6D Ball Valve

API 6D Ball Valve